This calculator is designed to assist you in determining the necessary materials for constructing an exterior stud wall.

Typical stud spacings in residential framing include 16″ O.C. (on center) and 24″ O.C.

If your wall includes corners, you must specify the number of corners using the designated option. Each corner selected will necessitate the addition of one stud.

For partition walls extending from this wall, the partition option will account for two studs for each added partition. The need for these additional studs depends on your wall layout or framing method.

The calculation of sheathing material is based on standard 4′ x 8′ sheets, derived from the square footage of your wall. Additional sheets may be required based on the dimensions of your wall.

Wall Calculator

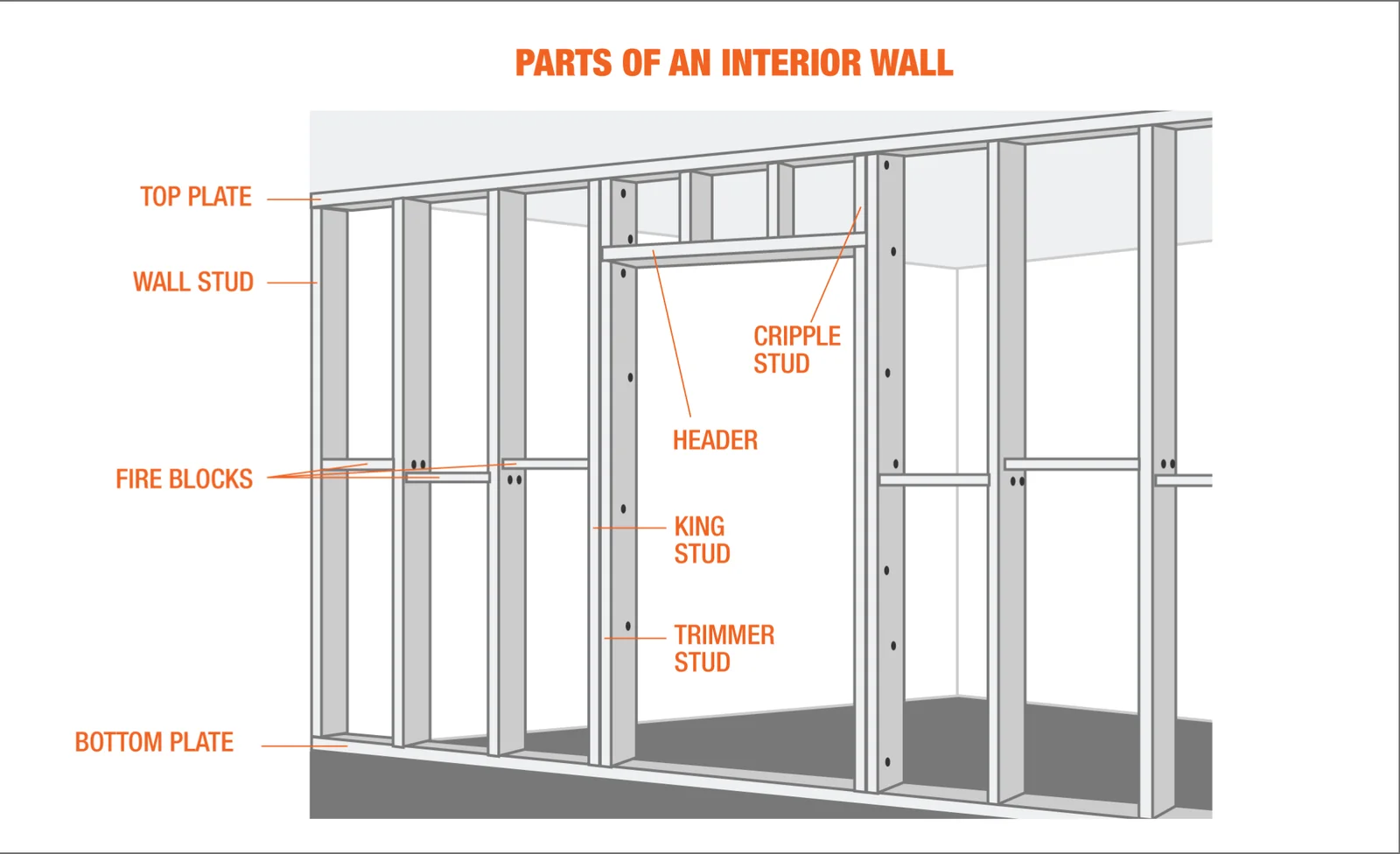

What are Stud walls in Framing?

Stud walls are foundational elements in construction, providing structural support and defining spaces within a building. Calculating the materials needed for stud walls is crucial for accurate budgeting and efficient construction.

How do you calculate stud wall materials?

Calculating stud wall materials involves determining the quantity of studs, plates, sheathing, and other components required for construction. Here’s a step-by-step process:

Measure Wall Dimensions: Begin by measuring the length, height, and width of the wall. Ensure accuracy to avoid material wastage or shortage.

Determine Stud Spacing: Choose the desired on-center spacing for studs, typically 16 inches or 24 inches. This spacing influences the number of studs needed and affects structural integrity.

Calculate Studs: Divide the length of the wall by the stud spacing to determine the number of studs required. Account for additional studs at corners and where partition walls intersect.

Estimate Plates: Calculate the linear footage of bottom and top plates needed for the wall. One bottom plate and two top plates are common in framing.

Determine Sheathing: Estimate the number of sheathing sheets required based on the wall’s square footage. Standard sheathing materials are often available in 4′ x 8′ sheets.

Account for Other Materials: Consider additional materials such as nails, screws, insulation, and vapor barriers based on project requirements.

How do I calculate how much framing material I need?

Calculating framing material involves determining the quantity of lumber or engineered wood products required for framing walls, floors, and ceilings. Follow these steps:

Measure Wall Length: Measure the total length of walls to be framed, including both exterior and interior walls.

Determine Stud Spacing: Choose the desired on-center spacing for studs, typically 16 inches or 24 inches, depending on building codes and structural requirements.

Calculate Studs: Divide the total wall length by the stud spacing to determine the number of studs needed. Round up to the nearest whole number.

Estimate Plates: Calculate the linear footage of bottom and top plates needed for the walls. One bottom plate and two top plates are standard in framing.

Consider Additional Framing Members: Account for headers, cripples, blocking, and other framing components based on wall openings, structural loads, and architectural plans.

Account for Waste: Factor in a waste allowance of 10-15% to accommodate cutting, trimming, and minor errors during construction.

How many studs do I need for a 12×12 room?

To calculate the number of studs needed for a 12×12 room, follow these steps:

Determine Stud Spacing: Choose the desired on-center spacing for studs, typically 16 inches or 24 inches.

Calculate Studs for Each Wall: For a 12×12 room with four walls, calculate the number of studs needed for each wall separately.

Example Calculation: Assuming 16-inch on-center spacing, the length of each 12-foot wall will require 9 studs (144 inches ÷ 16 inches = 9 studs). Since there are four walls, the total number of studs needed is 36.

Account for Corners: Include additional studs at each corner where walls meet.

Adjust for Windows and Doors: Subtract the area of windows and doors from the total wall length and adjust the stud count accordingly.

How do you calculate wall material?

Measure Wall Dimensions

Calculating wall materials involves determining the quantity of materials needed to cover or finish a wall surface. The first step is to measure the length and height of the wall to calculate the total square footage of the wall surface.

Choose Wall Material

After measuring the wall dimensions, the next step is to select the desired wall material. This could include options such as paint, wallpaper, tile, or paneling, depending on your preferences and the desired aesthetic of the space.

Calculate Square Footage

Once you’ve chosen the wall material, you’ll need to calculate the total square footage of the wall surface. This is done by multiplying the length of the wall by its height, resulting in the total square footage to be covered or finished.

Estimate Material Quantity

With the total square footage determined, the next step is to refer to the product specifications of the chosen wall material. These specifications will typically include the coverage area per unit of the material (e.g., coverage per gallon for paint, coverage per roll for wallpaper, coverage per box for tiles). Divide the total square footage by the coverage area per unit to estimate the quantity of material needed.

Consider Additional Factors

Finally, it’s important to consider additional factors that may affect the quantity of materials needed. This includes accounting for waste, which can occur due to trimming, cutting, or imperfect application. Additionally, factors such as pattern matching (for wallpaper or tile) and extra material for future repairs or touch-ups should be taken into consideration to ensure adequate coverage and a satisfactory finish.

How to Use this Calculator:

- Length of Wall: Enter the length of the wall in feet. This represents the horizontal span of the wall you intend to construct.

- Stud Spacing: Specify the on-center spacing of the studs in inches. Common stud spacings in residential framing are typically 16″ O.C. (on center) and 24″ O.C.

- Height of Wall: Input the height of the wall in feet. This indicates the vertical extent of the wall you plan to build.

- # of Corners: If your wall requires corners, input the number of corners here. Each corner adds one additional stud to the framing.

- # of Partition Walls: If other walls intersect or connect with the wall you are framing (partition walls), specify the number of these walls here. Each partition wall adds two studs to the framing.

Important Notes:

- Stud Spacing: Stud spacing refers to the distance between the center points of adjacent studs. It’s crucial for structural integrity and proper installation of sheathing materials.

- Corners and Partitions: Consider the layout and design of your wall. If it includes corners or connects with other walls (partition walls), ensure to account for these in your calculations.

- Sheathing Material: The calculator estimates the amount of sheathing material required based on using standard 4′ x 8′ sheets. Additional sheets may be needed depending on the dimensions of your wall.

Once you’ve entered all the necessary information, click the “Calculate” button, and the calculator will provide you with estimates for:

- Plates: The linear footage of plates needed, including one bottom plate and two top plates.

- Studs: The total number of studs required for framing.

- Sheathing: The number of sheathing sheets needed for covering the wall.

- Area of Wall: The total square footage of the wall surface.

This tool aims to streamline the planning process for your construction projects, providing accurate material estimates for efficient and effective framing of exterior stud walls.

Frequently Asked Questions

What is the standard spacing for studs in residential framing?

The most common stud spacings in residential framing are 16 inches on center (O.C.) and 24 inches on center (O.C.).

How do I account for waste when calculating materials?

It’s recommended to include a waste allowance of 10-15% to accommodate cutting, trimming, and minor errors during construction. This extra material helps ensure that you have enough coverage and allows for any unexpected circumstances that may arise during the installation process.

Can I use different sheathing sizes for my wall?

Yes, while 4′ x 8′ sheets are standard, other sizes may be available. When using different sheathing sizes, adjust calculations accordingly based on the chosen sheathing size. Ensure that you accurately measure the dimensions of the wall surface and select the appropriate sheathing size to cover the area effectively.

How do I calculate material for walls with irregular shapes or openings?

For walls with irregular shapes or openings, it’s best to break down the wall into smaller, manageable sections. Calculate the material needed for each section individually by measuring the length and height of each portion. Then, sum the totals to get the overall material requirement for the entire wall. This approach ensures accurate estimation and helps prevent over or underestimation of materials needed for the project.