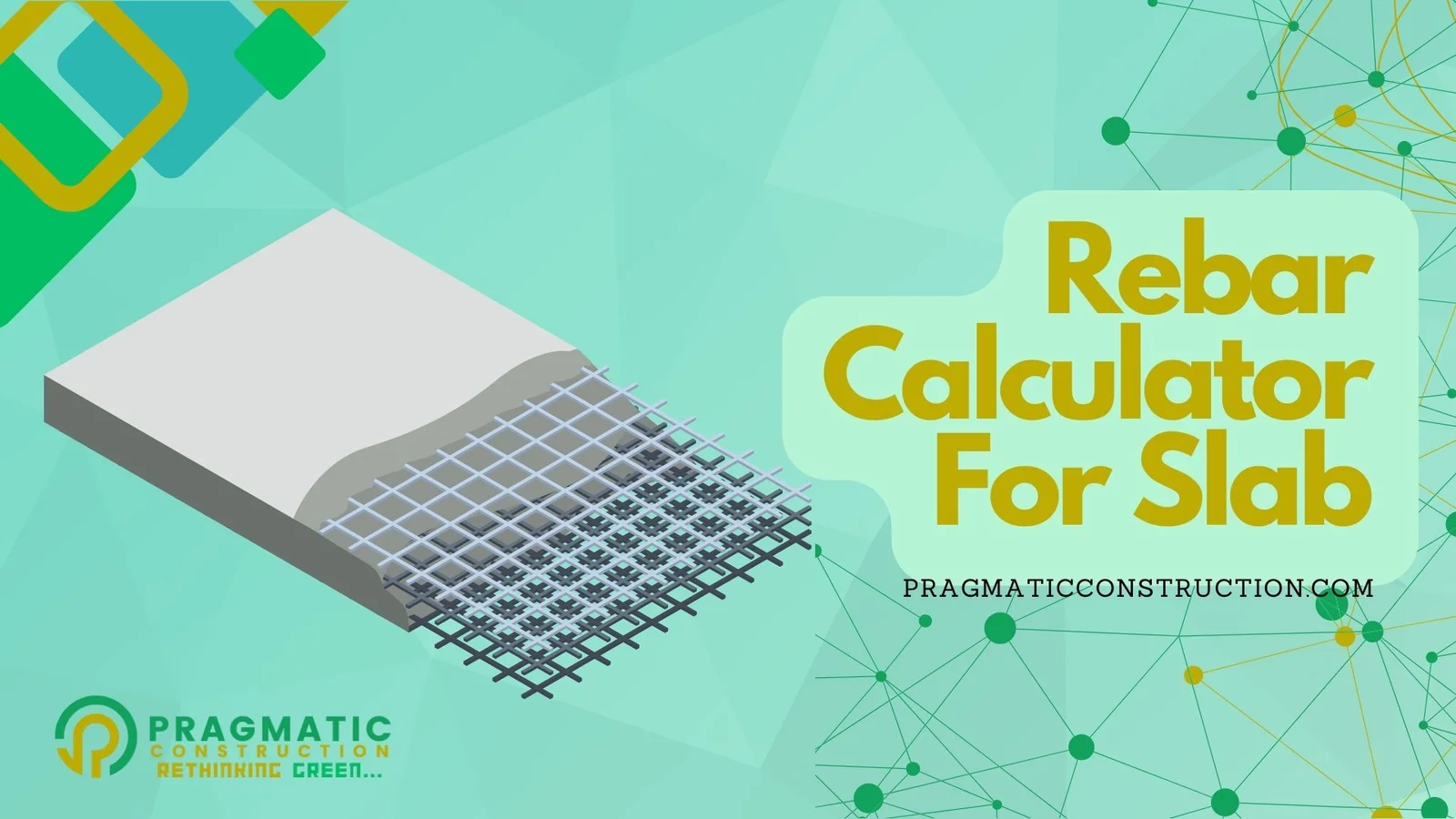

Reinforcing concrete slabs and driveways with rebar is essential for enhancing their strength and durability.

Calculating the required amount of rebar accurately is crucial to ensure structural integrity and longevity.

In this guide, we’ll delve into the step-by-step process of calculating rebar reinforcement for slabs and driveways, covering everything from understanding the calculation parameters to executing the calculations effectively.

Concrete Slabs

Concrete slabs serve as crucial components in various construction projects, providing stable foundations for buildings, driveways, and other structures. Reinforcing these slabs with steel rebar enhances their strength, durability, and resistance to cracking.

Role of Reinforcement in Slab

Reinforcement, typically in the form of steel rebars, plays a vital role in concrete slabs for driveways and foundations. Its primary functions include:

- Enhanced Strength: By adding tensile strength to concrete, reinforcement helps prevent cracking and structural failure under load or environmental stresses.

- Crack Control: Reinforcement acts as a barrier against crack propagation, minimizing the risk of surface cracks and ensuring the slab’s integrity over time.

- Load Distribution: It distributes loads more evenly across the slab, reducing the risk of localized stress concentrations and structural failures.

- Durability: Reinforcement increases the durability of concrete slabs by mitigating the effects of shrinkage, temperature fluctuations, and other environmental factors.

Design of rebar

The design of reinforced concrete slabs for driveways and foundations involves several critical steps:

- Site Assessment: Evaluate soil conditions, drainage, and load requirements to determine the appropriate slab thickness and reinforcement specifications.

- Load Analysis: Consider anticipated loads, such as vehicle traffic for driveways or building loads for foundations, to calculate design loads and determine the required slab thickness and reinforcement layout.

- Reinforcement Layout: Determine the spacing, size, and placement of steel rebars based on design calculations and industry standards. Consider factors like grid spacing, bar diameter, and splice lengths.

- Clear Cover Requirements: Establish the minimum clear cover, which refers to the distance between the surface of the rebar and the edge of the concrete, to ensure adequate protection against corrosion and fire resistance.

- Expansion Joints: Incorporate expansion joints to accommodate thermal expansion and contraction, preventing cracking and maintaining the integrity of the slab.

Construction Process & Rebar Installation

Proper installation of reinforcement is critical to the performance and integrity of concrete slabs. Here are the key steps involved in installing rebar for concrete slabs:

- Preparation: Prepare the site by excavating, leveling, and compacting the subgrade to provide a stable foundation for the concrete slab.

- Rebar Placement: Place the reinforcement according to the design specifications, ensuring proper spacing, alignment, and clearance from the slab edges.

- Tying and Support: Securely tie intersecting rebar pieces using wire ties or mechanical connectors. Provide adequate support, such as chairs or spacers, to maintain the reinforcement at the desired elevation within the concrete slab.

- Integration with Formwork: Integrate the rebar with the formwork or molds used to shape the concrete slab, ensuring proper positioning and alignment during concrete placement.

- Concrete Pouring: Pour concrete evenly over the reinforcement, using vibration or compaction techniques to eliminate air voids and ensure proper consolidation around the rebar.

- Curing: Protect the freshly poured concrete slab from premature drying and cracking by implementing appropriate curing methods, such as water curing or membrane curing.

Understanding the Calculation

Before diving into the calculation process, it’s vital to understand the key parameters involved:

Length and Width: These dimensions represent the length and width of the slab or driveway, expressed in feet and inches.

Grid Spacing: The grid spacing refers to the horizontal and vertical spacing between rebar, typically measured in inches. It determines the distribution of reinforcement across the surface.

Splice (Overlap): The splice or overlap is the length by which rebar segments must overlap to ensure proper bonding and continuity. It’s measured in inches and is crucial for maintaining structural integrity.

Waste Factor: The waste factor, expressed as a percentage, accounts for any material wastage during installation. It helps in estimating the additional length of rebar needed to accommodate wastage.

Concrete Slab Rebar Calculator

Now, let’s walk through the step-by-step calculation process:

- Input Data: Begin by entering the length and width of the slab or driveway in feet and inches. Then, specify the grid spacing and required splice length in inches. Finally, input the waste factor if necessary.

- Calculating Rebar Needed: Utilizing the input data, the calculator computes the amount of rebar required in lineal feet. It considers the dimensions of the area and the spacing between rebar to determine the total length needed.

- Accounting for Waste: The waste factor is applied to calculate the additional length of rebar required to accommodate wastage during installation. This value represents the amount the waste factor will add in lineal feet.

- Total Rebar Length: The sum of the calculated rebar length and the additional length due to the waste factor yields the total lineal feet of rebar required, including waste.

- Number of Rebar Lengths: To facilitate installation planning, the total length of rebar is divided by the standard length of rebar segments, typically 20 feet. This calculation provides the number of 20-foot lengths of rebar needed for the project.

Rebar Calculator for Concrete Slab

Checking Rebar Placement and Clear Cover:

After the installation of reinforcement, it's essential to verify the correct placement and clear cover to ensure the structural integrity and durability of the concrete slab. Here's how to check rebar placement and clear cover:

- Visual Inspection: Conduct a visual inspection of the reinforcement to ensure it matches the design layout, with proper spacing, alignment, and overlap as specified.

- Measurements: Use measuring tools, such as tape measures or calipers, to verify the spacing between rebar elements and the distance from the reinforcement to the slab surface (clear cover).

- Cover Meters: Utilize cover meters, electronic devices specifically designed for this purpose, to accurately measure the clear cover over reinforcement and identify any deviations from the specified requirements.

- Quality Assurance: Implement quality assurance procedures, including periodic inspections during installation and post-installation checks, to confirm compliance with design drawings and specifications.

Importance of Clear Cover in Reinforced Concrete Slabs:

Clear cover, the distance between the surface of the concrete and the nearest reinforcement, plays a critical role in the performance and durability of reinforced concrete slabs. Here's why clear cover is essential:

- Corrosion Protection: Adequate clear cover protects the reinforcement from exposure to moisture, chemicals, and environmental elements that can cause corrosion and deterioration over time.

- Bond Strength: Maintaining the prescribed clear cover ensures sufficient bond strength between the concrete and reinforcement, preventing slippage or separation under load.

- Fire Resistance: Clear cover provides a thermal barrier that helps protect the reinforcement from high temperatures during fire events, preserving the structural integrity of the concrete slab.

- Structural Performance: Proper clear cover enhances the structural performance of reinforced concrete slabs by preventing premature failure, cracking, or spalling due to corrosion-induced deterioration.

Conclusion

Reinforcement is a vital component of concrete slabs for driveways and foundations, contributing to their strength, durability, and structural performance.

By understanding the role of reinforcement, following the design process meticulously, adhering to proper installation practices, checking rebar placement and clear cover, and recognizing the importance of clear cover, builders and engineers can ensure the successful construction of high-quality concrete structures that withstand the test of time.

Incorporating these principles and best practices into concrete slab projects will result in safer, more resilient, and long-lasting driveways and foundations.