When embarking on a roofing project, accurately estimating the amount of plywood or OSB (Oriented Strand Board) needed for sheathing is crucial for budgeting and planning purposes. The roof sheathing calculator provides a convenient and efficient way to determine the quantity of sheathing material required based on the dimensions and specifications of the roof.

Whether it’s a gable roof or a hip roof, this calculator takes into account various factors such as building dimensions, overhangs, roof pitch, and waste percentage to provide accurate results.

In this comprehensive guide, we’ll delve into the functionality, inputs, instructions, and significance of the roof sheathing calculator in optimizing material usage for roof construction projects.

- Roof Decking Sheathing Calculator

- What is Roof Sheathing?

- Different Types of Roof Sheathing:

- Types of Plywood for Roofing:

- Is Roof Sheathing Necessary?

- Roof Sheathing Estimate – The Process

- How to use this Roof Sheathing Calculator

- Features of the Calculator

- Best Plywood for Roof Sheathing:

- Replace Plywood Roof Sheathing:

- Plywood Used for Roof Sheathing:

- Best Wood for Roof Sheathing:

- Best Plywood for Roof Decking:

- Best Material for Roof Sheathing:

- Plywood 4×8 Sheets for Roofing:

- Screws for Plywood Roof Sheathing:

- Conclusion:

Roof Decking Sheathing Calculator

What is Roof Sheathing?

Roof sheathing, also known as decking, is the layer of material that covers the rafters or trusses of a roof structure. It provides a flat and stable surface onto which roofing materials are installed. Roof sheathing plays a critical role in distributing the load of the roof evenly across the supporting structure, enhancing structural integrity, and providing a barrier against weather elements such as wind, rain, and snow.

Different Types of Roof Sheathing:

Several materials can be used for roof sheathing, each with its own characteristics and advantages:

- Plywood: Plywood is a popular choice for roof sheathing due to its strength, durability, and dimensional stability. It consists of thin layers of wood veneer glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another for added strength.

- Oriented Strand Board (OSB): OSB is another common option for roof sheathing. It is made from compressed wood strands bonded together with adhesive under high pressure and heat. OSB is known for its affordability and consistent performance.

- Wood Boards: Traditional wood boards, such as planks or tongue-and-groove boards, were commonly used for roof sheathing in older construction. While still occasionally used in historic renovations or specialized applications, they have largely been replaced by plywood and OSB due to their higher cost and susceptibility to warping and splitting.

Types of Plywood for Roofing:

When it comes to plywood for roofing, certain types are more suitable for the demands of roof sheathing:

- CDX Plywood: CDX plywood is a common type used for roof sheathing. The “CDX” designation indicates that it has one C-grade face (common) and one D-grade face (lower quality). It is suitable for applications where the appearance of the finished surface is not a concern.

- ACX Plywood: ACX plywood features one A-grade face (premium) and one C-grade face. It is often used in applications where appearance matters, such as exposed ceilings or when the roof decking will be visible from below.

- Treated Plywood: Treated plywood is chemically treated to enhance its resistance to decay, rot, and insect damage. It is recommended for use in regions with high humidity, frequent rainfall, or where the risk of moisture intrusion is elevated.

Is Roof Sheathing Necessary?

Yes, roof sheathing is necessary for several reasons:

- Structural Support: Roof sheathing provides structural support for the roofing materials and helps distribute the weight of the roof evenly across the supporting framework, such as rafters or trusses.

- Weather Protection: Roof sheathing acts as a barrier against weather elements, including wind, rain, snow, and hail. It helps prevent water intrusion into the interior of the building, protecting the underlying structure and interior finishes.

- Attachment Surface: Roof sheathing provides a flat and stable surface onto which roofing materials can be securely attached. It ensures proper installation and helps maintain the integrity of the roof covering over time.

Roof Sheathing Estimate – The Process

The roof sheathing calculator is designed to streamline the estimation process for plywood or OSB needed to sheath a roof. Its functionality revolves around key parameters that influence the amount of material required:

- Building Length and Width: These parameters represent the dimensions of the building, specifically the length and width of the gable side wall for a gable roof.

- Eave Overhang: The eave overhang is the distance from the outside edge of the wall to the eaves of the roof. It accounts for the extension of the roof beyond the walls and affects the total roof area.

- Gable Overhang: For gable roofs, the gable overhang refers to the extension of the roof beyond the gable end walls. It impacts the overall roof area and material requirements.

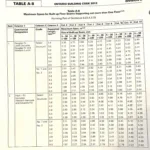

- Roof Pitch: The roof pitch, expressed as the ratio of vertical rise to horizontal run (e.g., 6:12), determines the steepness of the roof slope. It influences the surface area of the roof and, consequently, the amount of sheathing material needed.

- Waste Percentage: The waste percentage represents the amount of material that may be discarded or lost during the sheathing process due to cutting, fitting, and installation. It’s typically preset at a default value, such as 10%, but can be adjusted based on project-specific factors.

How to use this Roof Sheathing Calculator

Using the roof sheathing calculator involves straightforward steps:

- Input Parameters: Enter the building length in feet and inches, building width (gable side wall) in feet and inches, eave overhang in inches, gable overhang in inches, roof pitch (expressed as a ratio), and waste percentage (preset at a default value).

- View Results: Once the parameters are entered, the calculator computes and displays the following results:

- Roof Area: The total surface area of the roof in square feet.

- Estimated Plywood Needed: The number of sheets of plywood or OSB required based on the exact square footage of the roof.

- Waste Factor Adds: The number of sheets the waste percentage will add to account for material waste.

- Plywood Needed Including Waste: The total number of sheets needed, including the waste factor.

Features of the Calculator

The roof sheathing calculator offers several benefits for roofing projects:

- Accurate Material Estimation: By considering various parameters such as building dimensions, overhangs, roof pitch, and waste percentage, the calculator provides accurate estimates of the amount of plywood or OSB needed for roof sheathing. This helps contractors and builders procure the right amount of material, minimizing excess and reducing costs.

- Time and Cost Savings: The calculator streamlines the estimation process, saving time and effort that would otherwise be spent on manual calculations. Additionally, by optimizing material usage and reducing waste, it contributes to cost savings for roofing projects.

- Enhanced Planning and Budgeting: Accurate material estimation enables better planning and budgeting for roofing projects. Contractors can confidently plan their material purchases, allocate resources efficiently, and ensure smooth project execution.

- Improved Efficiency and Productivity: With precise estimates provided by the calculator, contractors can work more efficiently, avoid delays due to material shortages, and maintain productivity on site. This ultimately contributes to timely project completion and client satisfaction.

Best Plywood for Roof Sheathing:

Choosing the best plywood for roof sheathing depends on factors such as budget, climate, and specific project requirements. However, CDX plywood is a popular and widely used option for roof sheathing due to its strength, durability, and cost-effectiveness. It provides reliable performance and meets the necessary structural requirements for most roofing applications.

Replace Plywood Roof Sheathing:

Replacing plywood roof sheathing involves several steps:

- Assessment: Start by assessing the condition of the existing roof sheathing. Look for signs of damage, decay, rot, or water infiltration that may necessitate replacement.

- Remove Old Sheathing: Carefully remove the old sheathing using pry bars, hammers, or reciprocating saws. Take care to avoid damaging the underlying structure or adjacent roofing materials.

- Install New Sheathing: Cut new plywood panels to size and install them over the rafters or trusses, ensuring proper alignment and spacing. Secure the panels with appropriate fasteners, such as nails or screws, following the manufacturer’s recommendations and local building codes.

- Seal and Finish: Seal the seams and edges of the new sheathing with a waterproof sealant or flashing tape to prevent water intrusion. Finish the installation by installing drip edge flashing and other necessary roofing components.

- Roof Covering Installation: Once the new sheathing is in place, proceed with installing the selected roofing materials according to manufacturer guidelines and industry best practices.

Plywood Used for Roof Sheathing:

Plywood used for roof sheathing should meet certain quality standards and specifications to ensure durability and performance. CDX plywood is a commonly used option for roof sheathing due to its strength, affordability, and widespread availability. It is suitable for most residential and commercial roofing applications and provides reliable structural support for various roofing materials.

Best Wood for Roof Sheathing:

While plywood is the most common material used for roof sheathing, other types of wood may be suitable for specialized applications or historic renovations. The best wood for roof sheathing depends on factors such as local climate, building codes, and project requirements. Pressure-treated lumber or specialty woods may be recommended for regions prone to high humidity, termites, or other environmental factors that can affect wood durability.

Best Plywood for Roof Decking:

For roof decking applications where appearance matters, such as exposed ceilings or visible roof decks, ACX plywood is often preferred. ACX plywood features one premium-grade face (A-grade) and one common-grade face (C-grade), providing a smooth and uniform surface suitable for finishing or painting. It offers enhanced aesthetic appeal while maintaining structural integrity and durability.

Best Material for Roof Sheathing:

The best material for roof sheathing depends on factors such as budget, climate, project requirements, and local building codes. Plywood and OSB are the most common materials used for roof sheathing, offering a balance of strength, durability, and cost-effectiveness. The choice between plywood and OSB often comes down to personal preference, availability, and specific project considerations.

Plywood 4×8 Sheets for Roofing:

Standard plywood sheets for roofing are typically sized at 4 feet by 8 feet, providing a convenient and manageable size for installation. These sheets are readily available at most lumberyards, home improvement stores, and building supply outlets. They can be easily transported, handled, and installed on-site, making them ideal for various roofing applications.

Screws for Plywood Roof Sheathing:

When securing plywood roof sheathing, it’s essential to use the appropriate screws to ensure a secure and reliable attachment. Common options include:

- Roofing Nails: Roofing nails, specifically designed for use in roofing applications, are a traditional and widely used fastener for securing plywood roof sheathing. They are available in various lengths and gauges to accommodate different thicknesses of sheathing material.

- Deck Screws: Deck screws are another option for securing plywood roof sheathing. They feature coarse threads and a corrosion-resistant coating, making them suitable for outdoor use and exposure to weather elements. Deck screws provide strong and durable fastening for plywood sheathing and are available in various lengths and sizes.

- Galvanized Screws: Galvanized screws are treated with a protective zinc coating to enhance corrosion resistance and durability. They are suitable for use in outdoor applications, including roofing, where exposure to moisture and weather elements is a concern. Galvanized screws provide reliable and long-lasting fastening for plywood roof sheathing.

Conclusion:

The roof sheathing calculator is an invaluable tool for contractors, builders, and homeowners involved in roofing projects. By simplifying the estimation process and providing accurate material requirements based on project-specific parameters, the calculator enhances efficiency, reduces costs, and facilitates better planning and execution of roofing projects. Whether it’s for a gable roof or a hip roof, this calculator empowers users to optimize material usage, minimize waste, and achieve optimal results in roof construction.